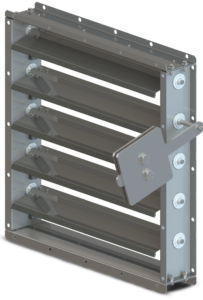

Our professional team is trained to successfully undertake your manufacturing project, from the CAD design to the final assembly of your product. Utilizing our high-performance machines and software, we can transform a sheet metal into your product through laser cutting, bending, and welding. Once the sheet is processed, we can perform the final assembly of your innovation. For your turnkey manufacturing projects, Industries B37 has the expertise required.

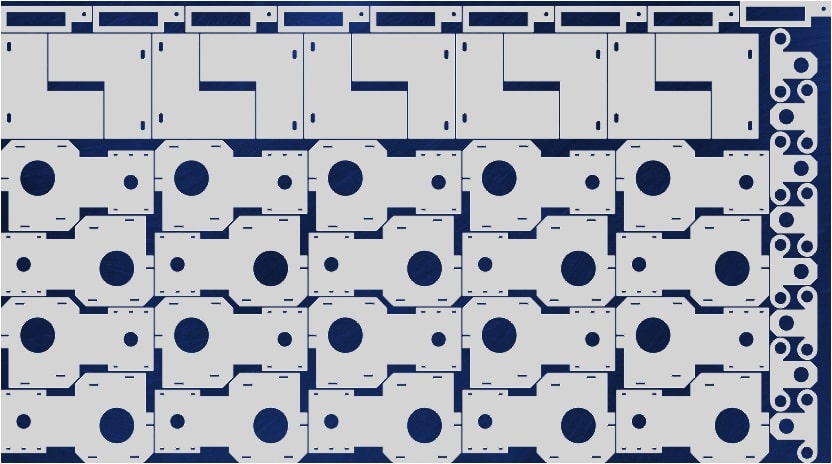

Using our Intelligent Nesting software, we can optimize material utilization, machine motion, manpower, and data management. Our engineering department can help you with the design, drafting or even small adjustments of your parts. Moreover, we can directly import any major 2D and 3D file for painless part creation.

Our CO2 laser machine provides a high cut edge quality, yielding parts that do not need rework. Sheets of up to 1/2" (mild steel) thickness can be cut with a smooth and clean finish.

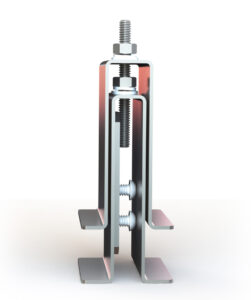

The results from sheet metal bending are crucial in order to avoid problems later down the production line. Our operators are trained to effecively and precisely operate the equipment, for the parts to meet your requirements.

Welds are critical to the integrity of any fabrication involving metal to be joined. Our expert welders not only have extensive hours of welding experience but patience, focus, and a keen eye are also part of their toolbox.

CUTTING BED

48 in x 120 in

MATERIAL THICKNESS

Mild Steel : up to 1/2 in

Stainless Steel : up to 1/4 in

Aluminium: up to 1/4 in

MATERIALS

Mild Steel

Stainless Steel

Aluminium

Galvanized

Thicknesses : up tp 1/4 in

Lengths : up to 8ft

Power Generation

Aerospace

Lighting

Transportation

Space Flight

Sports Equipment

Healthcare

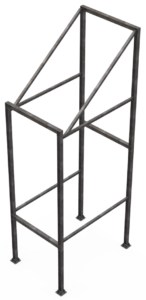

Construction

Aerospace

Architecture

Construction

Steel Fabrication

Construction

Machinery